ISO 9001 : 2015

Product categories

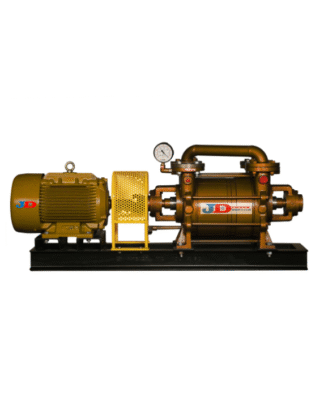

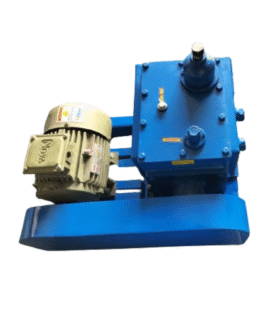

Vacuum Pump For Chemical Industry

JD VACUUM SERVICE chemical vacuum pumps are the industry's preferred choice because they safely and reliably handle explosive gases and corrosive vapors.

- Type: WATER RING VACUUM PUMP

- Power: 3 to 90 hp

- Voltage: 220 - 440 V

- Max Flow Rate: 50 to 2025 M3/HR

- Motor Speed: 1440 RPM

- Vacuum: 710 MM/HG

- Usage/Application: Chemical industry

- Country of Origin: Made in India

Description

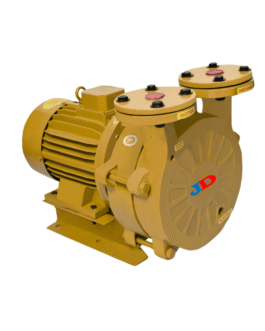

Vacuum Pump For Chemical Industry

Introducing the JD VACUUM SERVICE Vacuum Pump, engineered specifically for the demanding requirements of the chemical industry. This vacuum pump for chemical industry purposes is designed to handle corrosive gases and vapors. It provides a reliable solution to enhance productivity and meet stringent operational standards. Whether for filtration, distillation, or evaporation processes, this pump guarantees to deliver outstanding performance. Importantly, it reduces downtime.

Advanced Technology and Durability

The JD VACUUM SERVICE Vacuum Pump incorporates advanced technology that ensures optimal performance and longevity. This feature makes it an ideal pump for chemical industry tasks. Made with high-quality materials, it exhibits excellent resistance to chemical corrosion. This significantly extends its service life. Its robust design minimizes wear and tear. Therefore, you can rely on it for even the most challenging applications without compromise.

Ease of Use and Maintenance

Catering to the needs of the modern chemical facility, our vacuum pump is designed for ease of use. The vacuum pump for chemical industry settings has a simple setup process and intuitive controls. Consequently, you can get your operations running swiftly and efficiently.

Moreover, maintenance is straightforward, allowing your team to focus more on productivity rather than equipment upkeep. The vacuum pump’s user-friendly features exemplify JD VACUUM SERVICE’s commitment to quality and convenience.

Benefits of Liquid Ring Technology

- Benefits of Liquid Ring Technology

- Cool running, liquid ring technology

- Process-compatible seal liquid

- Low maintenance, high reliability

- Wear-free performance – no metal-to-metal contact

- Handles carryover and moisture-laden gas streams

| Type JDWV | Speed rpm | suction capacity | Recommended motor hp | Water consumption ltr/min. |

|---|---|---|---|---|

| 1 | 2850 | 50 | 3 | 7 |

| 2 | 2850 | 80 | 5 | 10 |

| 3 | 2850 | 120 | 7.5 | 14 |

| 4 | 1440 | 160 | 7.5 | 15 |

| 5 | 1440 | 220 | 10 | 20 |

| 6 | 1440 | 330 | 15 | 30 |

| 7 | 1440 | 440 | 20 | 40 |

| 8 | 980 | 720 | 30 | 60 |

| 9 | 980 | 845 | 35 | 80 |

| 10 | 980 | 1080 | 40 | 100 |

| 11 | 725 | 1500 | 65 | 150 |

| 12 | 725 | 2025 | 90 | 200 |