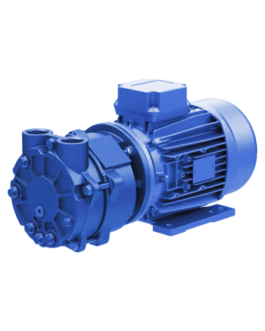

Water Ring Vacuum Pump

JD VACUUM SERVICE is a leading manufacturer and supplier of Water ring vacuum pumps at a reasonable price from Ahmedabad, Gujarat, India.

| Type | WATER RING VACUUM PUMP |

| Recommend Moto | 3 HP to 90 HP |

| Max. Vacuum | 710 mm of Hg. |

| Max. Capacity | 50 to 2025 M3/hr |

| Usage/Application | Industries |

| Country of Origin | Made in India |

Description

JD VACUUM SERVICE presents the Water Ring Vacuum pump,also known as aLiquid Ring Pump. This product is, therefore, made using high-quality components and, in addition, modern technology. We have also followed international quality norms. Our customers will appreciate our product. We offer our products at economical prices.

Water Ring Vacuum Pump / Liquid Ring Pump

A liquid-ring pump is a rotating positive-displacement pump.

They are typically used as a vacuum pump, but can also be used as a gas compressor. The function of a liquid-ring pump is similar to a rotary vane pump, with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal.

They are, therefore, an inherently low-friction design, with the rotor being the only moving part. Consequently, sliding friction is limited to the shaft seals. Moreover, liquid-ring pumps are typically powered by an induction motor.

Use Of Water Ring Vacuum Pump

Liquid-ring vacuum pumps can use any liquid compatible with the process, provided it has the appropriate vapor pressure properties, as the sealant liquid. Although the most common sealant is water, almost any liquid can be used. The second most common is oil. Since oil has a very low vapor pressure, oil-sealed liquid-ring vacuum pumps are typically air-cooled. For dry chlorine gas applications, concentrated sulfuric acid is used.

Water ring vacuum pump working principle

The casing of the machine is cylindrical, and, furthermore, it has a control disc on either side. Additionally, an eccentrically located impeller with curved blades rotates within the casing. The liquid (preferably) introduced is set into rotary motion by the blades, thus forming the water ring concentric with the casing.

Cells are formed between the ring and the blades of the impeller, which vary in volume from maximum to minimum with each revolution. The conveying medium enters the working chamber through the opening in the lateral control discs and is compressed by the decrease in volume of the cells. It then flows together with the cooling through the discharge opening in the control discs to the delivery port.

MOC of Pump

- Type: A (C.I. Construction)

- Type: C (All Internal Parts in SS 304 / SS 316)

- Type: SS (Complete SS 304 / SS 316)

Features

- Simple Construction

- High Capacity

- Trouble-Free Operation

- Low Maintenance

Applications

- Chemical Industries

- Pharmaceuticals

- Sterilizing

- Distillation, Evaporation & drying

- Filtration Processes

- Dehydrates

- Conveying Sucking

TECHNICAL SPECIFICATIONS

| Type JDWV | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Speed rpm | 2850 | 2850 | 2850 | 1450 | 1450 | 1450 | 1450 | 980 | 980 | 980 | 725 | 725 |

| Water consumption Ltr/min. | 50 | 80 | 120 | 160 | 220 | 330 | 440 | 720 | 845 | 1080 | 1500 | 2025 |

| Recommended motor hp | 3 | 5 | 7.5 | 7.5 | 10 | 15 | 20 | 30 | 35 | 40 | 65 | 90 |

| Water consumption ltr/min. | 7 | 10 | 14 | 15 | 20 | 30 | 40 | 60 | 80 | 100 | 150 | 200 |

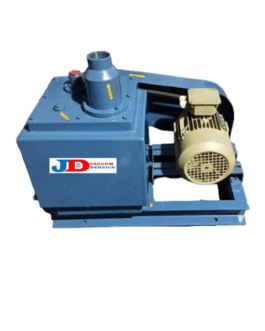

JD VACUUM SERVICE provided Twin Lobe Roots Blower for Maximum Output with Minimal Energy.

Frequently Asked Questions

What types of fluids can be handled?

Water ring vacuum pumps can efficiently manage gases, vapors, and humid air. However, they are not suitable for handling flammable or highly corrosive substances without proper precautions.

What industries commonly use water ring vacuum pumps?

These pumps find applications in numerous industries, including pharmaceuticals, food processing, and waste treatment, proving their versatility across various sectors.

What are the advantages of choosing a water ring vacuum pump?

Besides versatility, water ring vacuum pumps are energy-efficient and provide quiet operation, making them an attractive choice for many businesses. Their environmentally friendly operation, using water instead of oil, is a significant bonus for eco-conscious companies.

In summary, water ring vacuum pumps are valuable assets in many industrial applications due to their effective operation, ease of maintenance, and versatility. Exploring this technology can help businesses streamline their processes and achieve reliable outcomes.