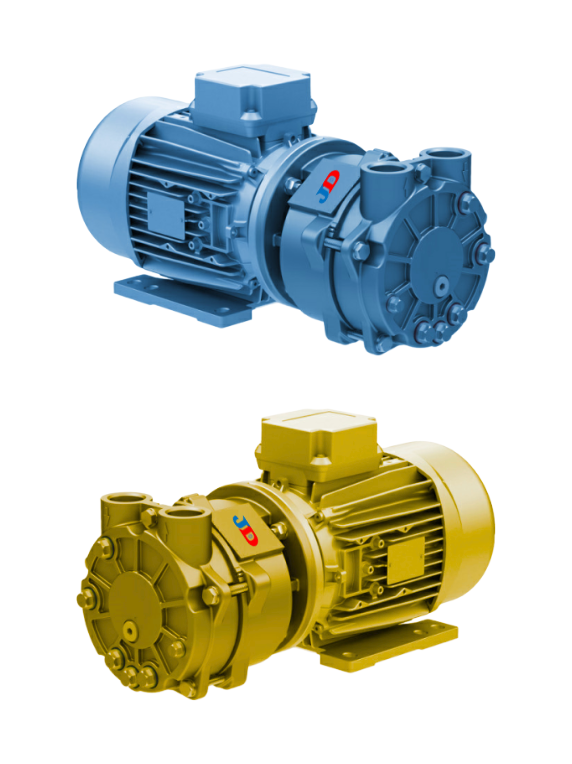

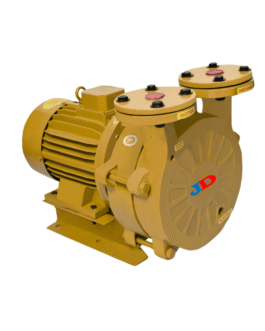

Rotary High Vacuum Pump

Choose our Rotary High Vacuum Pump for superior efficiency and reduced operational costs. Enhance your projects with precision engineering!

| Type | Rotary High Vacuum Pump |

| Brand | JD VACUUM SERVICE |

| Max. Vacuum | 760 mm of Hg. |

| Recommend Moto | 0.25 HP to 20 HP |

| Max. Capacity | 3 to 1050 M3/hr |

| Usage/Application | Industries |

| Country of Origin | Made in India |

Description

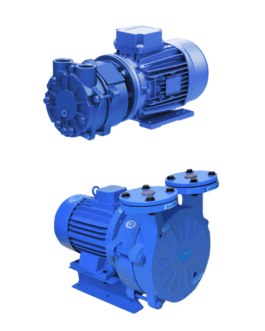

Rotary High Vacuum Pump

Welcome to precision engineering at its best with our Rotary High Vacuum Pump. It is designed to deliver unparalleled performance and reliability for a range of applications. Whether you are in the scientific research field or the electronic industry, this pump stands out as a superior choice. It is ideal for any domain requiring high vacuum solutions.

The Rotary High Vacuum Pump effectively reduces pressure and expels residual gases. It ensures optimal operation in various environments.

Superior Design and Technology

What sets our Rotary High Vacuum Pump apart is its unique design and advanced technology. Featuring a robust construction and utilizing state-of-the-art materials, this pump provides outstanding durability and service life. The innovative rotor design minimizes wear and energy consumption, translating to lower operating costs. Additionally, it operates quietly, making it an ideal option for environments where noise levels are a concern.

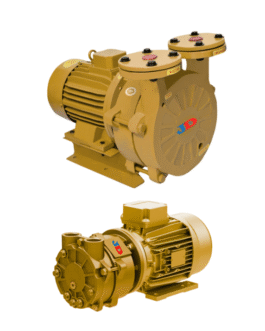

Applications and Versatility

This Rotary High Vacuum Pump is versatile enough to cater to a multitude of applications. From laboratory experiments to industrial processes, its capacity for achieving deep vacuum levels is noteworthy. This characteristic makes it a preferred choice in various sectors.

The pump’s ability to handle different gases expands its usability. Thus, it is suitable for tasks ranging from material handling to chemical processing. Trust in the Rotary High Vacuum Pump to elevate your operational efficiency while maintaining the highest standards of vacuum technology.

In conclusion, when you choose our Rotary High Vacuum Pump, you’re investing in a solution that brings reliability and excellence to your workflow. Experience the difference today and see how it can transform your vacuum-related tasks.

Key Features and Considerations

- Ultimate Vacuum: The lowest pressure the pump can achieve. High vacuum pumps typically reach pressures below 10−3 Torr.

- Pumping Speed: The volume of gas the pump can remove per unit time, usually measured in liters per minute (LPM) or cubic meters per hour (m3/h).

- Single-Stage vs. Double-Stage: Double-stage pumps can achieve a higher ultimate vacuum than single-stage pumps. They do this by compressing the gas in two successive stages.

- Oil-Sealed vs. Dry-Running: Oil-sealed pumps offer higher vacuum but have the potential for oil backstreaming into the vacuum system. Dry-running pumps provide a cleaner vacuum but typically have lower ultimate pressure.

- Gas Ballast: A feature in some oil-sealed pumps that allows a controlled amount of air during compression. This helps prevent condensation of vapors within the pump, which can contaminate the oil and reduce performance.

- Maintenance: Regular maintenance, including oil changes and vane inspection, is crucial. These steps are important for optimal performance and longevity.

- Noise and Vibration: Rotary vane pumps are generally quieter. They produce less vibration compared to some other types of vacuum pumps.